How To Repair Broken Brush Of A Dc Motor

Electric Motor Troubleshooting

Electric Motor Troubleshooting

How to Diagnose & Repair Electric Motors on Building HVAC Equipment

- Mail service a QUESTION or COMMENT most how to troubleshoot electric motors such as air workout compressor motors, heating equipment burner or fan motors, swimming pool motors, water well pump motors

InspectAPedia tolerates no conflicts of interest. Nosotros have no relationship with advertisers, products, or services discussed at this website.

Electric motor test & repair guide:

This article describes A/C electrical motor troubleshooting: here nosotros provide an electrical motor diagnostic table, a troubleshooting guide that helps diagnose and repair most electric motor bug for motors found on HVAC equipment in buildings such as air conditioners, furnace or air handler blower fans, oil burner motors, well pumps, and condensate return pumps.

Nosotros also provide an Commodity Alphabetize for this topic, or y'all can try the folio height or bottom SEARCH BOX every bit a quick style to find data you need.

A/C Electric Motor Troubleshooting Guide - Test Procedures

In this article we provide a diagnostic guide to decide and repair problems with electric motors. The page superlative photo was taken of of an oil burner electric motor not an air conditioning blower fan motor or pump motor, but y'all'll see that all of these electrical motors look a lot alike.

In this article we provide a diagnostic guide to decide and repair problems with electric motors. The page superlative photo was taken of of an oil burner electric motor not an air conditioning blower fan motor or pump motor, but y'all'll see that all of these electrical motors look a lot alike.

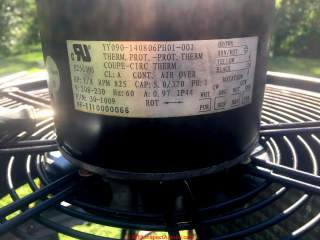

At left our photo illustrates the motor every bit typically establish in a straight-drive HVAC blower or air handler assembly. More about this air handler fan i

southward at BLOWER FAN Functioning & TESTING.

[Click to enlarge whatever prototype.]

Watch out: if yous are not trained in safe electrial wiring and test tool employ you should not fool with electrical motors or wiring. You could exist shocked or killed.

Article Series contents

- ELECTRIC MOTOR DIAGNOSTIC GUIDE

- A/C Electrical MOTOR COMPONENTS

- DMMs VOMs Prophylactic Use OF

- ECM MOTOR CAUSING Circuit BREAKER Buzz - blower motor troubleshooting

- ELECTRIC MOTOR DATA TAG

- Electrical MOTOR CENTRIFUGAL SWITCH or PTC PRD - bad switch, motor won't start

- ELECTRIC MOTOR OVERHEATS - 7 things to check

- Electrical MOTOR RUN DIRECTION

- Electrical MOTOR Commencement SWITCH

- ELECTRIC MOTOR TYPES - 8 types of single stage, split stage, two & 3 phase motors

- Electrical MOTOR WON'T START / RUN - 14 Things to Check

- ELECTRIC MOTOR OFF on RESET

- Electric MOTOR TESTS - Electrical Tests to Check HVAC Blower Fan Motor or Outdoor Compressor Fan Motor Winding on Heating or Cooling Equipment or on Other Electrical Motors

- Electrical MOTORS, 3-PHASE

- Electric MOTOR LIFE

- ELECTRIC MOTOR WIRING DIAGRAMS & GUIDES

While our page top photo shows the carmine reset push button most clearly, the reset push button on the motor at left may exist harder to spot. Sometimes the reset push on an electric motor is difficult to find, and sometimes in that location is no reset push button!

Fatal Shock Hazard Warning : Inspecting electric components and systems risks expiry by electrocution as well every bit serious burns or other injuries to the inspector or to others. Do non effort these tasks unless y'all are properly trained and equipped.

Run across DMMs VOMs Condom USE OF for help in making safe use of electrical test equipment before you start poking your meter probes into annihilation.

Basic Components of an A/C Electric Motor such as used on heating and air conditioning equipment

Before discussing how to diagnose air conditioner or heating organisation electrical motors allow's be certain we know what motor parts might exist involved. (Or skip right to Tabular array A if you prefer).

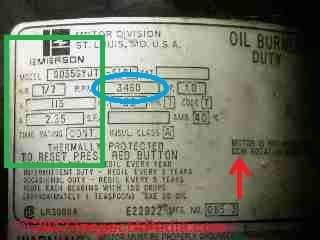

Photo: electric motor on a modern oil burner.

Photo: electric motor on a modern oil burner.

The electric motor has quite a few parts if examined in item, switches, wires, perhaps capacitors, oiling ports and more, but at that place are four basic parts to every HVAC electric motor:

- Electric motor rotor: the rotor follows (turns in the direction impelled by) the rotating magnetic field and thus spins the motor shaft

- Electric motor stator: the stator consists is a device or core containing offset and run windings (of copper wire) wound effectually a central core to create a magnetic field.

- Electric motor windings: the ii windings are used to create an electrical field in the stator.

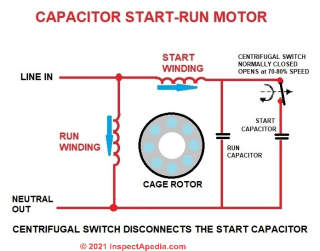

- Definition of Starting time winding: in an A/C (alternating current) electrical motor electrical current flowing through the start winding is used just to go the motor spinning from a stopped condition.

The start winding is asunder, commonly by a centrifugal switch, when the motor is upward to speed.

- Definition of Run winding: in an A/C electric motor the run winding is what keeps the motor spinning in one case it has started.

Current flowing through this winding produces a rotating magnetic field in the stator that keeps the motor shaft turning after the kickoff winding has turned off.

- Definition of Starting time winding: in an A/C (alternating current) electrical motor electrical current flowing through the start winding is used just to go the motor spinning from a stopped condition.

- Electric motor start switch: a centrifugal switch connects the A/C electrical ability to the motor to the start winding on the stator until the motor has reached a speed typically of 75-fourscore% of its full run speed (typically that's1725 rpm or 3450 rpm on newer high-speed oil burners).

In improver to the basic electrical motor components to a higher place in that location are two other features to know about when troubleshooting a motor.

How to Read the Information on an Electric Motor Information Tag

In our photo at left you lot tin can meet the notation on this electric motor data tag indicating the the motor is non-reversing and rotates counter-clockwise - designated by the words CCW ROTATION (red arrow).

In our photo at left you lot tin can meet the notation on this electric motor data tag indicating the the motor is non-reversing and rotates counter-clockwise - designated by the words CCW ROTATION (red arrow).

If you enlarge the photo [Click any image to see an enlarged, detailed version] you lot will see text above the red arrow noting that this is a Non-REVERSING motor.

See ELECTRIC MOTOR RUN Management

The blue oval marks the motor's rotating speed - 3450 RPM - this is a loftier speed oil burner. Older oil burners and equipment motors run at 1725 RPM. Some HVAC equipment uses a variable-speed electric motor.

The green rectangle marks other useful data in the data tag for this motor, fabricated by Emerson Electric in St. Louis MO. This is a 1/7 hp motor, designed for 115VAC, cartoon two.35A.

These data are helpful when diagnosing electric motor problems: using a DMM or VOM we can find unusual current draw above that ii.35A as a sign of trouble and we can bank check that the voltage level delivered by the electrical supply is shut to 115VAC 60 bike current single phase.

The motor's model number (SD55GYJTK-5181 in this case) is useful when replacing the motor or contacting the manufacturer for assistance.

An Electric Motor Time Rating designation is specified as CONT (continuous duty) - this motor is able to run continuously without damage or overheating under normal conditions.

A temperature rating (40C) and other data are given as well, including an explanation that this motor is. thermally protected and that should the motor'southward thermal protection switch trip off the user needs to printing the cherry push button.

Run across Electrical MOTOR OVERLOAD RESET

This motor'south information tag also includes oiling specifications indicating the required lubrication schedule, discussed

at ELECTRIC MOTOR LUBRICATION

Watch out: when ownership replacement electric motors, fuel units, and blower fan assemblies to exist sure they all are compatible. For example on oil fired heating equipment, the oil burner fuel units (the mechanical heating oil pump driven by the oil burner electric motor via a coupling) can exist purchased every bit CW or CCW devices. All three components have to be designed to rotate in a common direction:

- the electrical driving motor,

- the oil burner combustion air blower fan assembly, and

- the oil burner fuel unit or oil pump.

If the fuel unit is not rotated in the proper direction the heating appliance won't run - it won't receive fuel, and the driving motor and coupling parts may be damaged.

If a squirrel cage blower fan on an oil burner or inside of an air handler is spun backwards it will not move much air and equipment volition non function properly.

See ELECTRIC MOTOR RUN Direction

Electric Motor Lubrication Specifications & Schedules: when, how much oil, where to oil

For article loading speed we have moved this information

to Electrical MOTOR LUBRICATION

Electric Motor Thermal Overload Switch - the Thermal Switch

Details are at ELECTRIC MOTOR OVERLOAD RESET - separate article.

Electric Motor Showtime Switch Operation in Electric Motors

The first switch connects ability to the showtime winding to starting time the motor spinning. This feature is necessary because depending on the position in which the rotor stopped when the motor last turned off, the rotating electrical field created by the run winding can't outset the motor.

At CAUSES of HARD STARTING ELECTRIC MOTORS we explain how a failed starting capacitor OR depending on the motor design, a bad centrifugal switch can prevent a motor from starting.

A trained service technician may sometimes diagnose a failed starting time winding or failed showtime switch (centrifugal switch) by spinning the motor manually (potentially dangerous!). If the motor keeps running we suspect a bad start winding or bad first switch (run across diagnostic table details

at Table A: xiv THINGS to Bank check (in gild) if an A/C Electrical Motor Will Not Beginning.

When the electric motor has reached about 75-80% of its full speed the centrifugal switch opens, thereby disconnecting Ac electrical power from the offset winding. Power was already connected to and remains connected to the run winding.

So if the motor will start simply won't keep running, we suspect a bad run winding or bad wiring to the winding.

For electric motors used in most HVAC applications motor full speed is usually 1725 or 3450 rpm, though some equipment may use variable speed motors every bit well. The centrifugal switch volition open ("throwout") at about 2800 rpm for a 3450 rpm electric motor, and the centrifugal switch will open up at well-nigh 1400 rpm for a 1725 rpm electric motor.

Run across more details at Electrical MOTOR CENTRIFUGAL SWITCH or PTC PRD

Sparking Elecric Motor Repair

Reader Question: 12/22/2014 sparks when motor is running said:

When a table saw is turned on I run into sparks... what is the crusade and how to ready it

Reply:

Sparky,

Some sparking is normal within many electrical motors including table saws and drills, but no sparks ought to be seen exiting the device or its motor for obvious safe reasons.

Typically when I've seen sparks spraying out of a drill or tabular array saw I've establish that the motor brushes need replacement. A burned commutator in the electric motor is ofttimes the root trouble. Some light cleaning of the commutator may be needed. Have care non to score it. Remove the motor armature and sand it with very fine emery paper. Audit the amature while cleaning it

- If y'all see score or burn marks those need to be removed - otherwise the new brushes in the motor will not final long.

- If yous cannot make clean the copper armature sufficiently to remove scores and burns without sanding through the copper surface completely (I'd like to see at least 1/sixteen" remaining copper) then the part needs replacement.

- When y'all've finished cleaning the copper armature surface that contacts the motor brushes should be both shiny and very smooth. Supervene upon the motor brushes while yous're at it.

- When replacing the armature be Sure that you don't leave grit on the parts or in the bearings or you'll probably ruin the motor. While you're at it experience for side play when replacing this part - which may indicate worn-out bearings in the motor mount.

Basic Electric Motor Designs

Not all Electric Motors use a Starting Capacitor and/or Centrifugal Switch: hither we describe (in over-simpified terms) 8 Common Electric Motor Designs.

Single Phase Electrical Motors

- Unmarried stage, capacitor-start, capacitor-run motors: Many single-phase electrical motors may use a commencement and run capacitor to go the motor running and keep it running smoothly. The start winding and kickoff capacitor are cutting-out as the motor approaches full speed.

- Single phase, capacitor-start, capacitor-run, aux winding run motors: Some single phase electric motors employ a centrifugal switch to cut out the starting capacitor just keep the start winding in use as an aux winding equally the motor gets upwards to speed.

- Single-phase, no centrifugal switch: Other single stage motors have no centrifugal switch. When the motor reaches information technology total running speed the auxiliary winding remains in use, causing the unit to run as if information technology were a two-phase motor. This is considered a particularly-reliable electrical motor blueprint.

Split-Stage Electrical Motors

Divide-phase motors divide a single electrical current stage, sending it through two different windings that produce an electrical effect similar to motors run by a two-stage current source, producign a rotating electrical field to turn the motor.

Divide-phase motors divide a single electrical current stage, sending it through two different windings that produce an electrical effect similar to motors run by a two-stage current source, producign a rotating electrical field to turn the motor.

- Carve up-phase, capacitor-start, capacitor-run electric motors require both a starting capacitor and a smaller run capacitor. Usually a centrifugal switch is used to cut-out the starting capacitor equally the motor approaches its full running speed. The run cap remains agile.

- Divide-phase, capacitor-kickoff, consecration run motors use a starting capacitor but do not use a run capacitor. Usually a centrifugal switch is used to cutting-out the starting capacitor every bit the motor approaches its full running speed.

- Split up phase, resistance-start, induction-run motors practice not utilise starting nor run capacitors.

In a resistance-start consecration-run electrical motor, an out-of-phase status occurs considering the start-winding has higher electrical resistance than the run winding. For these motors, starting torque is created by the combination of the stator'due south magnetic field strength, the rotor's magnetic field strength, and the angle by which the 2 currents are out of phase with one some other.

The theoretical maximum torque would occur at 90° out of phase simply really inductive resistance differences between the thinner kickoff winding and thicker run winding volition typically produce a stage angle deviation between 35° and 40° - not not enough to give a strong starting torque.

Multi-Phase: 2-stage or three-Stage Electric Motors

Still other electrical motors utilise the rotating magnetic field produced a two-stage or three phase pattern both to starting time the motor and to keep it spinning.

- two-phase motors employ two separate windings oriented at xc° from one some other, "out of phase" with ane another, to produce a rotating magnetic field to turn the motor.

- three-phase motors apply three split up windings out of phase with i some other, also producing a rotating magnetic field to spin the motor.

In a split up-phase motor the stator uses ii separate windings: outset winding (smaller diameter wire) and a run winding (larger diameter wire). The start winding has higher electrical resistance thanthe run-winding, and it will be shut to the top of the stator's core.

The run winding volition be located about the bottom of the stator and will have the lower resistance of the ii windings. The two windings are connected electrically in parallel with ane another, as you lot can see in our sketch.

This blazon of stator can be used in both capacitor-first, capacitor run motors and in capacitor-start, induction-run motors.

The electric motor'due south stator contains four electrical poles, and the start winding is always located at 90° from the run winding. As electrical power is turned-on to the stator current will flow thorugh both the start and run winding at the aforementioned time, but considering of the college resistance of the start winding, its current flow is more in-stage with the source voltage than will be the electric current flow through the run winding. Therefore, the current flowing through the run-winding will lag backside the current flow through the commencement winding (due to inductive resistance).

It is the fact that there are and then two flowing currents that are out of phase with one another that a rotating magnetic field is created in the stator. The rotation speed of the magnetic field depends on the number of poles in the stator and the frequency of the source voltage (e.chiliad. 60hz or 50hz). Several sources give a simple formula for determining an electric motor'south rotating speed:

Speed = 120 x Frequency / Number of Stator Poles, or S = F/P.

Using the U.S 60Hz standard, we can calculate that a 2 pole motor should spin at 3600 rpm. (S or 3600 = 120 x 60 / 2)

Electric Motor Diagnostic Tests

How to Check HVAC Blower Fan Motor or Outdoor Compressor Fan Motor Winding on Heating or Cooling Equipment or on Other Electrical Motors

1. Simple Electric Motor Resistance Tests: Leads

Testing a blower fan motor winding: referring to the electrical diagram for your equipment, unplug electric connectors at the fan motor.

Measure the resistance between each atomic number 82 wire with a multimeter or VOM. The multimeter should be set in the X1 range.

For accuracy, don't measure when the fan motor is hot, allow it to cool off.

- When the resistance between each pb wire are those listed in the specifications for your equipment the fan motor should be normal.

- Aught resistance or infinite resistance are indicators of a problem .

two. Elementary Electrical Motor Resistance Tests: Windings

Test to make up one's mind if a motor winding (beginning winding or run winding) is non broken (open) or shorted (airtight). This examination tin be washed on well-nigh household appliance motors including both unmarried-phase and threer-phase electric motors.

With the VOM ready to the nearly-sensitive resistance or ohms scale (R 10 one), and with the meter zeroed, cheque the resistance betwixt the motor winding leads (you may need to cheque the motor's wiring diagram to be sure you lot're checking in the right spot).

- Normal: You should meet depression resistance, less than x ohms. That's normal.

- Zero or very depression resistance: Yous should not see very low resistance, close to goose egg. That suggests a shorted widing. The motor will probably blow a fuse or trip a circuit breaker when turned-on.

Very low resistance between a motor wiring terminal and the motor'southward metal case, that tin can mean that at that place is a short between a motor terminal and ground, probably through the motor's steel casing.

No resistance betwixt the start and run terminals to mutual, but resistance betwixt the start and run terminals, this means that the internal motor overload protection circuit is open. In this last example, allow the motor to cool and re-examination it before replacing it.

- Resistances over x ohms. If y'all see space resistance the winding has probably burned or broken.

Higher resistance readings probably mean that the winding is damaged while very high resistance readings or infinite resistance tell you that a winding is broken or "open".

Spotter out: when measuring resistance at very low levels, a poor connectedness with your probe or even having your finger in the circuit will foul upwardly the reading's accuracy.

Picket out: some damaged motor windings will test out just fine on the demote with the motor asunder completely, just when the motor begins to spin a damaged wire in the winding may, due to the centrifugal force of rotation, open, causing the motor to run poorly or to stop completely or to chatter.

More detailed VOM tests on motor leads and windings are given in our diagnostic table plant

at ELECTRIC MOTOR DIAGNOSTIC GUIDE

At Bones Electric TESTS for BURNED OUT COMPRESSOR MOTORS nosotros requite more details about resistance levels to expect when testing an electric motor.

3. Bank check electric motor offset / run capacitors

If your motor uses a outset/run capacitor, the capacitor could be defective.

If inspection by eye shows a capacitor that is bloated, burned, deformed, information technology needs to be replaced.

If by centre the capacitor looks ok information technology might yet be defective.

With the capacitor disconnected from the motor'southward wiring, with your VOM probes on the cap'south leads (examination start and common, then run and common separately if the cap is a combined beginning/run device) you will see the resistance rising from a low number every bit the capacitor begins to charge, driven simply by the ability source in your VOM itself.

Watch out: let the capacitor bleed-downward for ten-fifteen minutes before trying to echo this test or, as it nevertheless holds a charge your test will be in-valid.

Encounter details

at Test a MOTOR Outset or RUN CAPACITOR

More than electrical motor diagnostic guides and downloads are

at Electrical MOTOR WIRING DIAGRAMS & GUIDES

and in the REFERENCES section of this commodity

four. Bank check the Electric Motor'south Centrifugal Switch

Typically a centrifugal switch or mayhap a PTC or PRD drops the start capacitor from the motor'due south electrical circuit one time the motor has spun up to operating speed, or in some designs, a mechanical centrifugal switch may be used to disconnect the starting capacitor when the motor speed has reached a critical rpm, typically almost half of the motor's run speed.[2]

If your electric motor uses a centrifugal switch to cutting out the "offset" capacitor once the motor is up to speed, a failure of that switch tin cause motor failure.

Diagnostic details for a centrifugal switch used on elecric motors are

at ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

5. Bank check the electric motor's cooling fan

If your electrc motor is an "open" pattern yous can see into the motor housing; look for clots of dust and oil that may be blocking the cooling fan and causing the motor to overheat; overheating can cause the motor's thermal overload switch to shut the motor off (and the switch may pop out waiting to cool-down and re-set).

See details

at ELECTRIC MOTOR OVERLOAD RESET

5. Electrical Motor Circuit Assay - MCA

Excerpting from Andy Page, The Basics of MOTOR CIRCUIT Analysis [PDF] Reliable Plant, (Noria Corporation), 1328 E. 43rd Court, Tulsa, OK 74105 Tel: 800-597-5460; E-mail: pagea@alliedreliability.com, retrieved 9/13/12, original source: http://www.reliableplant.com/Read/10686/motor-circuit-analysis, Extract:

MCA online [tests performed while the motor is operating] can be further split into ii categories - current analysis and voltage assay.

Electric current analysis is primarily focused on the rotating components. Loose or broken rotor bars, cracked end rings, rotor eccentricity, misalignment and coupling/belt problems are some of the "large-hitter" failure modes detected in the current signature.

Power quality bug like harmful harmonics, voltage imbalances and under/over-voltages are among the issues identified with voltage analysis. MCA offline is most famous for the resistance-to-ground measurement. But other measurements make motor circuit defects easy to discover. Measuring electric characteristics like impedance, inductance and capacitance tell the analyst enough about the condition of the windings. Inductance is a bang-up indicator of plow-to-turn shorts. Capacitance to ground measures the amount of winding contamination (water, dirt, dust, etc.). Changes in each of these affect impedance (full resistance of an Ac excursion). These characteristics are measured phase to stage and phase to basis and compared to each other and to percent change from baseline to identify motor circuit defects. Motor circuit analysis (MCA) is often and hands confused with motor current assay (MCA), which is an abbreviated version of motor current signature analysis (MCSA).

Repair Article Recommendations by System Blazon

- Air conditioning or oestrus pump systems: to locate the various controls and switches for A/C or heat pump systems

see CONTROLS & SWITCHES, A/C - HEAT PUMP.

Also see THERMOSTATS, HEATING / COOLING.

- Heating systems: If you are looking for the chief burner reset buttonOn heating equipment y'all'll want to

run across: Aquastat Functions

and Cad Cell Relay Switch Flame Sensors (hot water boilers and some water heaters),

STACK RELAY SWITCH On older oil fired boilers and furnaces,

FLUE GAS SPILL SWITCH TRIPPING & RESET (gas fired equipment), and

LOW WATER CUTOFF CONTROLS On steam heating systems.

Condensate pump motors on steam heating systems are also discussed

at CONDENSATE RETURN PIPES, PUMPS, STEAM

- Thermal overload relays on electric motors used on air conditioning, heating, water supply and other building equipment may shut off an overheated motor and (if not automatic) may require a manual reset.

Run across ELECTRIC MOTOR OVERLOAD RESET SWITCH explanation (how to reset a motor off on reset).

- Water supply systems: Controls on well pumps and water supply equipment that may require reset or repair are discussed

at CONTROLS & SWITCHES on WATER TANKS.

Working with unmarried phase vs. 3-phase electrical motors

Reader comments on unmarried phase & iii Phase motors

Well-nigh single phase motors take ii sets of windings.

The main or chief windings are directly connected to the power lines while the motor in running. The second windings are usually thinner wires physically get-go from the main windings inside the motor.

The purpose of the secondary windings is to provide directional information and an initial strong kick to get the motor started turning. Once the motor is started, the master or main windings can keep the motor running just fine.

Less common, these secondary windings are directly powered from the ability lines through a run capacitor that provides a continuous time or phase shift to the windings. Also

run into HOW to CHOOSE a Starting time / RUN CAPACITOR

Far more common, the secondary windings and capacitor are powered through a centrifugal switch that is airtight for approximately ane/two 2nd on starting.

As the motor gets up to 2/three speed, the centrifugal switch opens and disconnects the secondary windings.

This switch is usually behind and function of the connection plate where y'all attach the power cables in the end of the motor.

Whatever niggling piece of dust can keep this switch from closing when the motor is stopped.

At this indicate, the motor just sits there and hums

see details at Bustling MOTOR SOUNDS from A/C or Rut Pump system

not knowing which style to go or how to get started.

Just knocking this one little dust particle off makes the repair, and the motor volition run fine henceforth. Most of the time yous have to pull the back end of the motor off to become to this switch.

See details at Electrical MOTOR CENTRIFUGAL SWITCH or PTC PRD

Reversing the direction of the current in the secondary windings reverses the direction of the motor. This tin can usually be washed by switching the leads to the secondary windings. Sometimes ane of the secondary leads is attached to a primary windings and you lot take to dig into the windings to find it and separate it out.

You can buy electronic stage converters to generate a third leg which piece of work reasonably well, but generally works for just one electric motor at a time. The converter must be somewhat closely matched to the motor in size. It converts AC to DC, then creates an bogus third leg electronically. This arroyo is most 80-85% constructive in that y'all demand to derate the driven motor by 15% or so.

You tin employ any 3 phase motor to generate the third leg if yous can get information technology started. I have read about people using a small-scale unmarried stage motor to get a bigger 3 phase motor going, or using a pull rope wrapped around the motor shaft to pull kickoff the big 3 phase motor.

Once running, a 3 phase motor will generate a third leg which yous can use to run other 3 phase motors. Y wound motors work much better than a Delta wound motors in this approach. This is nigh 65-70% effective.

I recollect you tin can use a capacitor to the tertiary leg much similar single phase motors to generate enough of a phase offset to get the 3 phase motor started.

The shocked client may have used the 3 phase motor to run the compressor directly. He probably needed a skilful unloader to forestall the motor from getting bogged down by the compressor until the motor got up to speed. The center of the Y windings may have been attached to the neutral or ground wires, but probably would be shifted towards the third leg.

You can buy commercial rotoconveters designed to generate 3 stage from 2 phase.

They look like a motor with no output shaft and accept an fastened large box containing a batch of capacitors. The rotating armature of a three stage motor on its own will generate a weak 3rd leg that will probably exist somewhat phase shifted towards the 2nd leg.

The capacitors are attached between the first and third leg, which will generate a leading current towards the first leg, somewhat offsetting the shift towards the second leg. Adding a few more turns would generate a larger voltage output from the generated third leg. I accept never taken a rotoconverter apart, then this is just a good guess. Rotoconverters brand a very clean 3rd stage from single phase , approaching is 90-95% effectiveness.

You can run multiple 3 phase motors of unlike sizes simultaneously. The motors actually help each other. Rotoconverters are somewhat noisy, maybe ii-three times that of an equivalent motor. Otherwise they work very well.

I have employ a rotoconverter for 20 years to run my mill and metallic lathe. I am running a 5 hp lathe on a iii hp converter and accept never managed to slow it down. Rotoconverters are often used oil companys to run remote oil extraction pumps

It is cheaper to purchase the converter than to pay for the miles of copper for the tertiary leg from the power company. - 2022/03/31 from Ozzie

Also see LOST NEUTRAL SHOCKS HOMEOWNER- a three-phase motor "converted" to unmarried phase becomes unsafe

Typical Life of an Electric Motor

I agree with y'all that the beliefs sounds abnormal. There might be something in the local surroundings such equally unusual moisture or even corrosive gases, or low voltage, or another installation result that could be a factor.

Certainly plenty of blower motors run in daily use for decades. Let'south both do some inquiry on electric motor failure rates as a function of climate such as Florida. And let's both report dorsum hither

Research on Expected Life of Electric Motors

- Brancato, Emanuel L. "Estimation of lifetime expectancies of motors." IEEE Electric Insulation Magazine 8, no. 3 (1992): 5-xiii.

Abstract;

Methods for evaluating lifetime expectations are discussed. Factors that affect the life of bearings and brushes and of wire coil insulation are identified. Thermal life of insulation and methods for accelerated testing are discussed.Examples are included to assist in the calculation of such factors as motor temperature-rise conditions and the benefits to be realized through upgrading the thermal classification of the motor insulation organization.

- De Kleine, Robert D., Gregory A. Keoleian, and Jarod C. Kelly. "Life bike optimization of residential air-conditioner replacement." Ann Arbor: Academy of Michigan (Retrieved from Center for Sustainable Systems, Report No. CSS10-02) (2010).

- Henderson, H. I., & Sachs, H. M. (2006). The Efficacy of SEER as a Seasonal Performance Measure

for Different Climates. Symposium on Improving Building Systems in Hot and Humid

Climates (ESL‐HH‐06‐07‐twoscore). - Hamilton, Robert John. "DC motor brush life." IEEE Transactions on Industry Applications 36, no. vi (2000): 1682-1687.

- Kimura, K., T. Iwabuchi, Thousand. Morooka, and Y. Ishikawa. "Fundamentals-a useful index for estimating residuum life of motor insulation." IEEE Electrical Insulation Magazine 6, no. 2 (1990): 29-32.

- Hamilton, Robert John. "DC motor brush life." In Conference Record of 1998 IEEE Industry Applications Conference. 30-Third IAS Annual Meeting (Cat. No. 98CH36242), vol. 3, pp. 2217-2224. IEEE, 1998.

- Cheung, K. South. P., and B. Westward. Darvell. "Fatigue testing of a NiTi rotary instrument. Office ane: strain–life relationship." International endodontic journal 40, no. 8 (2007): 612-618.

I had a three ton Trane Parcel unit of measurement installed less than iii years ago from a reputable company in Miami, FL. In less than 3 years, my blower motor had to exist replaced twice. To me, that sounds crazy and like something is just not right either with the unit or the install

Company says its due to humidity / environmental conditions etc. I alive in Miami my whole life, never remember whatever other Air-conditioning units needing a new blower motor yearly. Is this normal beliefs for a practically new AC?

This Q&A were posted originally at BLOWER FAN Operation & TESTING

Electrical Motor Wiring Diagnostic Gides, Wiring Diagrams, Parts, Repair Guides

Lookout man out: if yous are non trained in proper, safe electrical work, stay out of your electric motor - you could be shocked or killed.

- Baldor INSTALLATION, OPERATION AND MAINTENANCE OF RELIANCE® STANDARD INDUSTRIAL AC INDUCTION MOTORS - [PDF] Baldor Electric Company P.O. Box 2400 Ft. Smith, AR 72902-2400 United states Tel: (501) 646-4711

book of wiring diagrams for the same series of motors produced afterwards nether Baldor

- Baldor, BALDOR MOTOR Nautical chart [PDF], NEMA Quick Reference Nautical chart to NEMA Frames & Motor Properties, Brownell Motors and Drives

- Baldor, BC254 REGEN DC MOTOR SPEED CONTROL INSTALLATION AND OPERATING MANUAL [PDF] (2001) Baldor Electric Co., - retrieved 2022/04/04 original source: https://www.baldor.com/Shared/manuals/730.pdf

- BASIC ELECTRICAL TESTS for BURNED OUT COMPRESSOR MOTORS

- BETTA-FLO JET PUMP INSTALLATION MANUAL,[PDF] National Pump Company, 7706 Due north 71st Ave., Glendale, AZ 85303, Tel: (800) 966-5240 Email: info@natlpump.com, website: http://www.nationalpumpcompany.com, retrieved afresh ix/13/12, original source: http://www.nationalpumpcompany.com/pdf/Betta_Flo_IOM_Jet_Pump.pdf

- BODINE ELECTRIC MOTOR Itemize & MANUAL [PDF] NR-2 - Bodlne Electric Visitor 2500 W Bradley Place Chicago. lllmo~s 60618

- BODINE GEARMOTOR HANDBOOK [PDF]

- BROWNELL MOTOR REPAIR PARTS CATALOG [PDF] Essex Brownell, Essex Group, Inc., 1601 Wall St., Fort Wayne IN 46801 U.s.a., Website: world wide web.superioressex.com Tel: 800-774-4643

- Burt, Charles Chiliad., Xianshu Piao, Franklin Gaudi, Bryan Busch, and N. F. Taufik. ELECTRIC MOTOR EFFICIENCY Under VARIABLE FREQUENCIES AND LOADS [PDF] Journal of irrigation and drainage engineering 134, no. 2 (2008): 129-136.

Abstract:This paper details a study performed by the Irrigation Preparation and Research Center to make up one's mind motor performances under varying speeds [induced by a variable frequency drives (VFD) controller] and loads.

A further goal of the report was to provide sufficient information to designers so that they could estimate full pumping plant power usage with a VFD-controlled installation.

Motors were tested with a VFD as well as across-the-Iine. On average, the relative efficiency of the electric system with a VFD may be approximately 8% lower than the relative efficiency of a properly designed, total-load beyond-the-line system.

If 1 considers actual field operating weather condition this 8% is misleading because overall free energy savings can be obtained with VFDs due to their ability to properly adjust speeds to meet bodily field conditions.

- COPELAND ELECTRICAL HANDBOOK [PDF]

- Dayton Electrical MOTOR WIRING DIAGRAM [PDF], Dayton Electric Mfg. Co., 5959 West. Howard St., Niles IL 60714 United states of america, retrieved 2022/07/09, original source: Grainger.com

- ELECTRIC MOTOR HORSEPOWER & CIRCUIT WIRE SIZE

- Electrical MOTOR RUN Management

- ELECTRIC MOTOR Racket DIAGNOSIS

- Electric MOTOR OVERLOAD RESET

- GE MOTOR INSTALLATION AND MAINTENANCE INSTRUCTIONS for NEMA 140 to 500 Frame Horizontal Air conditioning Small Industrial Motors GEI – 56128H [PDF]

- GENTEQ ECM ELECTRIC MOTOR INSTALLATION GUIDE for Evergreen CM electric motors, previously branded GE ECM Motors [PDF] (2014) Genteq®, 1325 Heil Quaker Blvd., LeVergne TN 37086, Tel: one-866-503-8566, Website https://www.genteqmotors.com Regal-Beloit Inc.,

Excerpt from the guide: In 2004 the Regal Beloit Corporation acquired General Electric's Commercial and HVACR Motors and Capacitors businesses with the correct to use the GE brand through 2009. These divisions were named GE ECM by Royal Beloit, GE Commercial Motors by Royal Beloit and GE Capacitors by Imperial Beloit.

In 2009, Regal Beloit announced the rebranding of those GE branded businesses nether the name Genteq, for markets that include residential and commercial HVAC equipment and electrical applications that employ capacitors.

With this rebranding, the Genteq logo took the place of GE ECM, GE Commercial Motors and GE Capacitors logos on all branded products, sales and marketing materials, Web sites, communications documents, signage and other related items.

- IRONTON ELECTRIC MOTOR OWNER'S Manual [PDF] Northern Tool Northern Tool + Equipment Co., Inc. Burnsville, Minnesota 55306 U.s.a. NorthernTool.com Fabricated in China - retrieved 2022/04/04 original source https://world wide web.northerntool.com/images/downloads/manuals/29560.pdf

- INSTALLATION, OPERATION AND MAINTENANCE OF RELIANCE® STANDARD INDUSTRIAL AC INDUCTION MOTORS - PDF, 180 – 449 Frames (NEMA), 112 – 280 Frames (IEC), Instruction Transmission B-3620-25, April, 2007, Baldor Dodge Reliance, P.O. Box 2400, Fort Smith, AR 72902-2400 U.South.A., Ph: (1) 479.646.4711, Fax (i) 479.648.5792, International Fax (1) 479.648.5895 Website: www.baldor.com

- Marathon, AC Induction MOTOR INSTALLATION Performance MAINTNENANCE INSTRUCTIONS [PDF] Air-conditioning Consecration Motors 56- 6800 Frames (NEMA) 63 – 280 Frames (IEC) MARATHON ELECTRIC Contact Motor Customer Service at: Phone: (715) 675-3311 world wide web.marathonelectric.com

- Marathon, Ac Induction MOTORS [PDF] 56-5000 Frame, Manufactured for Allen-Bradley past Marathon Electric, Inc., retrieved 2022/04/04 original source: https://literature.rockwellautomation.com /idc/groups/literature/ documents/um/1329m-um001_-en-p.pdf

Excerpts:

These instructions must be followed to ensure prophylactic and proper installation, operation and maintenance of the motor. They should be brought to the attending of all persons who install, operate or maintain this equipment.

- MOTOVAIRO USE & MAINTENANCE INSTRUCTIONS for ELECTRIC MOTORS [PDF] (2019) Motovario, Teco Group, Motovario S.p.A. Via Quattro Passi 1/iii 41043 Formigine (MO) Italy Tel. +39 059 579700 Paid-in Capital letter: Euro 18.010.000 i.v. Rea: R.East.A. di Milano n. 1863844 Website: www.motovario.com

- Qi, Fang, Daniel Scharfenstein, Claude Weiss, Clemens Müller, Ulrich Schwarzer ELECTRIC MOTOR HANDBOOK [PDF] (2019) Infineon, retrieved 2022/04/04 original source: https://world wide web.infineon.com /dgdl/Infineon-motorcontrol_handbook-Additional TechnicalInformation-v01_00-EN.pdf?fileId= 5546d4626bb628d7016be6a9aa637e69

Excerpts: This motor handbook was created by Infineon Technologies AG together with Institute for Power Electronics and Electrical Drives, RWTH Aachen University/ Germany.

The functioning principles and characteristics of the different types of electric machines are explained using brief auto descriptions, diagrams, tables etc. In contrast to other documentations on electric machines complex mathematical descriptions are avoided wherever possible.

The rotation direction can be set by the position of the capacitor in front end or behind of the auxiliary winding as can be seen in Figure eighteen.

- Sterling, Unmarried Phase ELECTRIC MOTOR INSTALLATION & MAINTENANCE MANUAL [PDF] (2006) Sterling Electric Co., Irvine, California (800) 474-0520 Indianapolis, Indiana (800) 866-7973 Hamilton, Ontario (800) 809-0330 e-mail service: sales@sterlingelectric.com www.sterlingelectric.com retrieved 2022/04/04 original source: https://www.sterlingelectric.com/manuals/Single Phase Motor O One thousand Manual 032106.pdfv

- TECO WESTINGHOUSE MOTORS & DRIVES Toll Book [PDF] TECO-Westinghouse Motor Company, 5100 Due north. IH-35, Round Stone TX 78681 USA, Website: world wide web.tecowestinghouse.com Tel: 1-800-873-8326 - itemize excerpt:

Our manufacturing plants are located in the U.South., Taiwan, Mexico, Malaysia, Australia, Peachy U.k. and Mainland china. A total line of induction, synchronous and DC motors and generators are bachelor in both horizontal and vertical configurations from 1/iv hp to 100,000 hp. Nosotros also offer complimenting Air-conditioning drive products

. - TEST a MOTOR Start or RUN CAPACITOR - how to article

- WEG, INSTALLATION AND MAINTENANCE MANUAL FOR NEMA LOW VOLTAGE Electric MOTORS [PDF] WEG Electric Motors Corp. 2100 Brighton-Henrietta Townline Road Rochester NY 14623 U.s.a. Tel: 716-240-thou , retrieved 2022/04/04 original source: https://www.stevenbrownassociates.com/ pdf/drivers/electric/weg/motor.pdf

Excerpt: This manual covers all the three-stage and unmarried-stage asynchronous squirrelcage consecration motors, from 140T to 580T frame sizes. The motors described in this manual are field of study to continuous improvement and all data is subject to modify without observe. For further details, delight consult WEG.

- WEG, SPECIFICATION of Electrical MOTORS [PDF] Op. Cit.

Excerpts:a ) Direct current motors

These motors are quite expensive requiring a straight current source or a converting device to catechumen normal alternate current into direct current. They are capable of operating with adjustable speeds over a broad range and are perfectly suited for authentic and flexible speed control. Therefore, their use is restricted to special applications where these requirements compensate the much college installation and maintenance costs.

b ) Alternating current motors These are the most frequently used motors because electrical power is usually supplied every bit alternate current.

The most common types are:

Synchronous motors: synchronous motors are 3-phase Ac motors which run at stock-still speed, without sideslip, and are generally applied for big outputs ( due to their relatively high costs in smaller frame sizes ).

Induction motor: these motors generally run at a constant speed which changes slightly when mechanical loads are applied to the motor shaft.

Due to its simplicity, robustness and low toll, this type of motor is the almost widely used and, in practical terms, is quite suitable for almost all types of machines.

Currently it is possible to control the speed of induction motors by frequency inverters.

- WWE, AC INDUCTION MOTOR IO Manual [PDF] Installation And Maintenance For Fractional Single-Phase and Polyphase AC Induction Motors This Manual Covers WorldWide Electrical's NT, NAT, NATE, NTJ, NATJ, NATEJ, WSSNV, WSS, NAWSS, NAWSSE, SSPE, FM, and FD Models - WorldWide Electric Corporation 3540 Winton Place, Rochester, NY 14623 Sales Support: (800) 808-2131 Technical Support: (844) 993-7378 www.worldwideelectric.cyberspace

- Too meet REFERENCES at the stop of this article

Reader Q&A - as well see the FAQs series linked-to below

@noah,

It could exist that the motor or a bearing in the motor is failing only a reasonable cheque that most service techs would brand is to

simply swap in a new start capacitor. That may give yous some more than life out of the motor.

I have a two speed electric motor for my married woman's Spa/Hot tub, but it only has a single commencement capacitor. The consequence is that the motor will start properly when ability is applied to the loftier speed terminal, just won't commencement (simply 'hums') when power is applied to the low speed terminal.

If I get the motor started with the high speed terminal so switch power to depression speed winding, it will continue to run only fine, but information technology won't beginning up on that winding. Information technology used to beginning up on either winding. What is the issue? I thought that if the capacitor was bad, it wouldn't start on either setting, simply starts fine on one just non the other.

@Peter Tozer,

I would expect for a loose electrical connection,

an excessive load beingness applied to the motor,

A bad bearing,

For if the motor is being controlled by a relay, a bad relay

I accept a 12 volt electric motor which goes start/stop/start/stop and and then on in very rapid succession when connected to the battery. what is incorrect with information technology?

@Chjris,

Nigh-often the motor problem you describe, loss of torque and increased current draw (until information technology trips the circuit billow) is acquired by

1. overloading of the motor: for instance if the compressor itself whose piston and other moving parts is failing due to article of clothing or poor lubrication or a bad bearing, or due to backpressure load on the compressor, and then the electric motor driving the compressor will confront an abnormally high load that in turn can cause the motor to overheat or describe excessive current. Ultimately the compressor itself may seize or the motor driving it may seize.

2. failing bearings in the electric motor itself, once more causing a resistance to turning or moving parts that leads to overheating of the motor itself, college electric current draw, until the motor trips the circuit billow; ultimately the motor itself may seize.

I take 2hp motor that will start. However, the longer it runs the less torque it has. and then it will popular the breaker, It goes on a compressor.

@Dennis E Strawn, reset of a tripped motor safety switch tin can require some time to allow the motor and overheat sensor to absurd downwardly.

And yes, depression voltage tin can prevent a motor from running or starting and might upshot in a humming motor.

Accept an air compressue motor that volition hum for a few seconds before stopp[ng. Has a reset push button on motor, but doesnt seem to reset. Have a voltage supply of 123 volts at present, but before I corrected the recepticle connection, it wasnt getting the 120 volts that it needed.

@Anonymous, in the recommended reading listing found at the end of the article above y'all volition desire to click on the link to the commodity titled

CAPACITORS for HARD STARTING MOTORS

0 you lot volition also come across in the article index or near the end of the commodity I but recommended other links to procedure for selecting the correct capacitor

I need aid with choosing the right capacitor could yous assistance me delight my email istalal 6611 9116 Gmail

Luis

If by undulating you are describing a motor whose speed seems to go on speeding up then slowing downwards,

I would showtime check the stability of the supply voltage to the motor.

Other possibilities are a declining bearing, overheating, a poor electric connection, or a winding that opens when the motor gets up to higher speed.

What is the cause of motor undulating?

If the air handler blower fan motor is not starting the problem could be a failed motor, begetting, or merely a bad motor capacitor.

You changed out the run cap only what about the starting capacitor?

Possibly you lot tin give me a little direction....'a/c wasn't working, turned fan to "on", no air from vents. Opened handler cover. Coils were cold/iced. I defrosted and cleaned with coil cleaning foam. Checked and cleaned drain line and dried the sensor. All the same no air out of vents

. If I turn off unit of measurement at the switch. And then plow information technology back on, I tin can hear the thermostat click, and the a/c unit 'picks'... then the internal fins in the blower are moving. I hear a kind of whump ... whump ... whump like some motor is trying to engage but cipher is happening.

Fifty-fifty thought the fan inside the unit is spinning, no air blowing from the vents. Is it fourth dimension to go outside and piece of work on the compressor part or could information technology still be something inside at the handler? Its Fri later thanksgiving, trying to fix this myself if its possible, or at least know exactly what the trouble is before I call in the "pros".

I have some electronics background and I have changed out the run capacitor ouside a few time. Usually if its that, the air does blow from the vents.

Since your motor is working information technology sounds every bit if the problem is with the wiring or a switch or control

I have an electric motor for a bed to lift and lower but now it simply goes 1 direction what could exist the problem

Bruce:

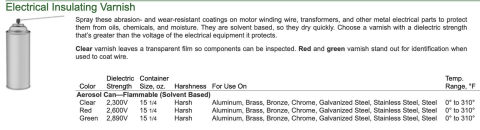

Companies who are adept in or who provide electrical motor re-winding services describe use of either varnish or a resin used to insulate the motor rewinding wire after repair.

Dreisilker describes four types of electric motor winding insulation methods; yous'll want to meet that guideline earlier buying anything. Y'all'll want to match your winding insulation method and material. The four methods are

1. Dip and bake: electric motor windings are dipped in varnish and then baked in an oven

2. Trickle varnishing: the motor windings are heated and spun to distribute the varnish

3. Vacuum Pressure Impregnation (VPI) a vacuum pressure tank filled with varnish is used to fully impregnate motor windings and insulation with resin or varnish.

four. Ultra-Seal - the electrical motor windings are impregnated with high molecular weight thermoset polymer resin.

- https://dreisilker.com/blog/four-types-of-motor-winding-insulation-methods/

Yous can see that some of these methods for electric motor winding insulation are pretty sophisticated and require special equipment. And so yous need to cull the method before buying varnish, another resin material, or thermoset polymer resin sealant.

In one case decided there are quite a few suppliers of resins and varnishes for sealing motor windings, and nigh 500 products among which to cull, including some elementary spray-on products; which and where you buy depend equally well on the state in which you're working.

Just one case is a spray-on motor winding varnish from

- McMaster-Carr, 9630 Norwalk Blvd. Santa Iron Springs, CA 90670-2932, USA Website: www.mcmaster.com Electronic mail: la.sales@mcmaster.com Tel: (562) 692-5911

Where practice I purchase all the insulation material for just one motor rewinding?

hendricksonbruce399@yahoo.com

Could exist a burnt winding or failing bearing or of course, depression voltage.

single phase electric motor tripped earth leakage and after remaking connections, runs again but at reduced speed

I have a single stage 240v motor running an air compressor. When tbis moto 3rd is running my lights on the same circuit flicker. What could exist causing this?

Is this a simple fix?

What are the Reasons for Low motor running Amps(7.5A@245V) in 2HP unmarried phase submersible Borewell pump set with start & run capacitor ??

Normal Running Amps :12.5A@245V

If main winding is faulty, and auxiliary winding is all correct, of submersible pump set motor with start & Run capacitor, then what would be the Running Motor Amps as main winding is already faulty ? (2HP Rating, single stage pump-set )

Lindy

Lindy

Take you checked to be sure that at that place are no switches that could be out of social club.

E.one thousand. a start winding power may exist turned off by a centrifugal switch.

I have the following fan motor model # SFC1-500B, 120V 60HZ 1.35A 162W. I am trying to figure out how to repair it. This is a learning project and not sure how to get past this part.

The red color wire has no continuity getting to the windings.

I checked information technology from one of the prongs on the ability cord.

The power cord is connected to a red wire that goes to a white wire that goes to the windings.

There is continuity to the white wire every bit y'all tin see under the insulation that disrepair into the windings. I check the winding to see if there is continuity and I get none. I should be able to bear on information technology with the multi-meter and become low resistance correct?

How exercise I cheque to run across if the coil can receive power from the ability cord? This seems similar the nigh obvious mode. If there a copper wire broken from the white wire located under the insulation?

Lak

Lak

If that motor is new and came with three other identical motors, and if it was wired properly but does not run, then the motor is lacking, mayhap seized or with a manufacturing defect - not something we tin decide from photo alone.

Withal higher up on this page we depict diagnostic testing procedures for such electric motors.

Hi we got 4 new motors and one likewise non working information technology's blower blazon ,I am giving direct supply 220v not with blower set up,for checking purpose but no one is rotating may i know the reason

Mike

That sounds like a failed motor or a shorted control or circuit

Right, Bob, that's why a service tech often "shotguns" a repair guess past swapping in a new cap.

Allow me know how that works.

I have an Electric motor on air compressor that starts and runs for well-nigh v seconds and trips breaker. Tried on several dissimilar circuits.

I gauge a replacement capacitor volition be a lot cheaper than a motor, and so I'll effort that first and allow you know. Thank you.

Yep that's possible.

hi and thanks for your respond. I have read the linked commodity and noted the possible reasons for my single phase motor going ACW rather than CW.

It may be that the fault/impairment had already been done before I bought it but I tin can't encounter how the motor'southward start widing connections could have been reversed, as being ane suggested possibility. Equally regards a failed electric motor starting capacitor, there is a small foursquare capacitor close to the manual switch. If this was faulty, could it influence the motor direction?

Bob

Let'southward commencement with diagnosing the cause then we can select the cure for an electrical motor that runs backwards. It may be that the motor was damaged or information technology may simply exist a wiring fault.

See details at Electric MOTOR RUN DIRECTION - backwards

afterwards checking there let me know yous y'all're progressing

My lawnmower, which I bought on eBay, is rotating the wrong style.

The single phase domestic electric motor has ii terminals/spades which I swopped over but no change.

The motor should rotate clockwise, looking on the spindle, which ties in with motor fan and grass impeller configuration. There is a capacitor side by side to the manual switch, if this particular was faulty could it have any effect on rotation?

The mower does cut the grass, throws most of the cuttings into drove box but besides scatters some around!

Would be grateful for any suggestions/solutions, thanks.

Lentikile

Bustling motor without running is often a bad start capacitor or a seized motor,

also can be low voltage or overloaded motor.

Anon

I don't know enough from your note to make a reliable guess at what'due south wrong with your motor, just yes, a motor winding sometimes opens upwardly only when the motor is spinning.

I've tested continuity because the motor only has one capacitor ando the wiring seems fine.could it be that the windings are damaged?

If a single stage automatic pump motor but makeso sound without running what could be the cause

Jimbo

That sounds to me similar a wiring error, damaged or shorted wire, or perhaps a lost or bad start capacitor. Information technology's possible that dis-assembly and re-associates nicked a wire or connector belonging to the beginning cap.

My 100v induction motor was squeling but running and starting fine. I found a bad begetting on the front end so I change both front and rear bearings.

Everything turns very smoothly by hand just when I plug information technology in it now only buzzes and blow the breaker.

Can't figure what I did wrong. All went dorsum together as originally. Finding it hard to believe it is the capacitor or centrifugal switch or contact since it ran earlier the bearing change. Ideas?

Jessie

I can't say with certainty just I think your elecrician will await at

- actual voltage being delivered to the loftier speed terminals

- pump wiring connections

- pump loading, bearings, h2o supply

Meanwhile, don't hook information technology upwards as you risk a fire (and may accept damaged the pump)

I have a single stage 220 Dual speed pump and when I claw the high speed side up it runs for well-nigh five seconds and then starts to smoke and shuts off but if I hook upward the depression side it runs fine why is this

Les

Watch out: What you describe is very unsafe risking an electrical stupor injury or worse.

You should unplug that motor immediately. Most likely the switch has either failed internally or is shorted internally. Information technology'due south possible that the wires to the switch accept go shorted together.

The 230V Rockwell motor on my table saw runs with the switch on or off. What could be the problem?

Wally

If the problem wear a switch that needed to exist reset then I don't think y'all would meet any movement in the fan when you turn power on

Motor doesn't outset when relay closes. Sometimes fan moves always so slightly. Changed capacitor simply no changed. I haven't pulled the motor assembly out from the enclosure notwithstanding. Could it possibly have a resetable overload switch?

COuld be a bad start capacitor

1hp air compressor. The motor simply humms when yous turn it on. You tin freely plough the pulleys when this happens. Maybe like starting out in overdrive going uphill.

It sounds to me similar you want the motor tested.

That's really would be less than the price of arbitrarily replacing the motor. There is something you tin do kickoff which is to remove the motor completely and simply ostend that the motor drive shaft volition spin freely.

If the bulldoze shaft doesn't spin easily or if information technology wiggles in its bearings, or if there is a lot of end play when yous move the motor drive shaft parallel to its centrality and so the motor is probably damaged or its bearings are shot.

A motor rattling dissonance or vibration may as well be a sign of failed motor bearings.

See details at RATTLING & VIBRATION noises from A/C or Heat Pump Organization

I take a Waterco Aquanature 50xl heat pump for my puddle.

After a normal cycle the fan stop, after the fan tries to start, only it takes 2-3 times before she gets going again at full speed.

I changed both capacitor (10uf 370v) and i however take the same problem. Anybody always heard of that trouble earlier ?

(relay practiced too) i thing it could be the motor but it's very expensive for just a test ? whatsoever assist (motor ane/8hp 825rpm 208-230) Thnx for your assist

Tobey:

Checking a condenser fan motor with a VOM or DMM in Ohms manner:

On a multi-speed fan yous'll find different resistances on different wires checked against the white fan wire - for an A/C or heat pump condenser fan.

Across that - which is model specific - a resistance of null beyond the motor usually means that there is an internal brusque, peradventure in the windings.

and infinite resistance typically means that there is an open up connector or open winding.

What is a condenser motor fan supposed to read when you ohm out

Ron, if nosotros assume the motor isn't overloaded then information technology sounds as if the motor is overheating, perhaps from a bad bearing. Check showtime, though, for depression voltage.

Small AC capacitor get-go motor. 1/two hp. It runs fine for x minutes, so stops running. Then buzzing trying to start once again, merely it cant. The beginning capacitor was burned out when I got it, but I replaced it.

Tabular array of Air-conditioning or Heating System or Other Electric Motor Troubleshooting Procedures for a Motor that Will Non Get-go

Table A: 14 Things to Cheque (in this order) if an A/C Electric Motor Will Not Offset is at present found

at ELECTRIC MOTOR WON'T Starting time / RUN - 14 Things to Bank check

Table of Air-conditioning or Heating System Electrical Motor Troubleshooting Procedures for a Motor that Overheats or Trips its Reset Push button or Runs at Abnormal Current or Voltage

Tabular array B: 7 Things to Check if an Electric Motor Starts but Overheats and Trips its Reset Button or Runs at Abnormal Voltage or Current Levels is now institute

at ELECTRIC MOTOR OVERHEATS

Table C: 7 Things to Cheque if an Electric Motor is Noisy

Table of Ac or Heating System Electrical Motor Troubleshooting Procedures for a Motor that is Noisy

For document loading speed we moved this information.

Delight see separate commodity: Electric MOTOR NOISE DIAGNOSIS

Which way does an Electrical Motor Run - Tin can Electric Motors run Backwards? Information plant on the electric motor's information tag.

Details for this topic take moved to Electric MOTOR RUN Management.

In short: check the motor label: uni-directional electric motors run just one way: clockwise (CW) or counterclockwise (CCW) just not both. Bi-directional & self-reversing electrical motors run in either direction, CW or CCW. Some electric motors can outset and run "backwards" following damage to the motor'southward beginning capacitor or windings.

...

Keep reading at ELECTRIC MOTOR OVERLOAD RESET or select a topic from the closely-related manufactures below, or meet the complete Article INDEX.

Or see ELECTRIC MOTOR DIAGNOSTIC FAQs - questions & answers posted originally at this folio.

Or run across these

Recommended Articles

- ELECTRIC MOTOR DIAGNOSTIC GUIDE - home

- A/C ELECTRIC MOTOR COMPONENTS

- BLOWER FAN Functioning & TESTING

- BURNED-OUT COMPRESSOR

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

- CHATTERING RELAY CONTROL SWITCHES

- COPELAND Electric HANDBOOK [PDF]

- Electric MOTOR 3-PHASE

- ELECTRIC MOTOR CENTRIFUGAL SWITCH or PTC PRD

- ELECTRIC MOTOR DATA TAG

- Electrical MOTOR HORSEPOWER & CIRCUIT WIRE SIZE

- Electric MOTOR LIFE

- Electrical MOTOR LUBRICATION

- Electric MOTOR NOISE DIAGNOSIS

- ELECTRIC MOTOR OFF on RESET

- Electric MOTOR OVERHEATS

- Electric MOTOR OVERLOAD RESET SWITCH

- ELECTRIC MOTOR RUN DIRECTION - backwards

- ELECTRIC MOTOR Kickoff SWITCH

- ELECTRIC MOTOR TESTS

- ELECTRIC MOTOR WIRING DIAGRAMS & GUIDES

- Electrical MOTOR WON'T START / RUN

- HARD STARTING COMPRESSOR MOTORS

- HARD STARTING Electrical MOTOR CAUSES

- OIL BURNER Noise Smoke ODORS - home

- OIL BURNER Dissonance DIAGNOSTIC INDEX

- RESET Push button, ELECTRIC MOTOR

- TIGHT or SEIZED Air-conditioning COMPRESSORS

- WATER PUMP PROTECTION SWITCH

Suggested citation for this spider web folio

Electric MOTOR DIAGNOSTIC GUIDE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED Articles: Article Alphabetize to Electrical INSPECTION & TESTING

Or utilise the SEARCH BOX found beneath to Enquire a Question or Search InspectApedia

...

Inquire a Question or Search InspectApedia

Try the search box just below, or if you adopt, post a question or comment in the Comments box below and nosotros will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may exist delayed: if your comment contains an prototype, spider web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been canonical by a moderator. Apologies for the delay.

Technical Reviewers & References

Click to Show or Hide Citations & References

Publisher InspectApedia.com - Daniel Friedman

How To Repair Broken Brush Of A Dc Motor,

Source: https://inspectapedia.com/electric/Electric_Motor_Diagnosis.php

Posted by: orrlittleth.blogspot.com

0 Response to "How To Repair Broken Brush Of A Dc Motor"

Post a Comment